APQP (Advanced Product Quality Planning)

INTRODUCTION

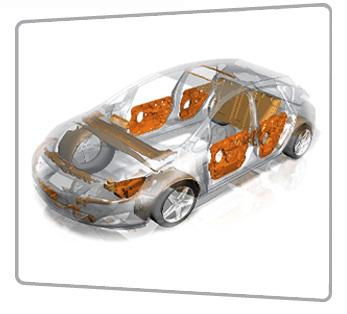

Advanced Product Quality Planning (APQP) is a set of procedures and techniques used to develop products in industry. Although, specifically for the automotive industry it has application in many other organizations. It is quite similar to the concept of Design For Six Sigma (DFSS).

It is a defined process for a product development system for organizations such as; General Motors, Ford, Chrysler and their suppliers. Its general objective is to produce a product quality plan which will support development of a product or service that will satisfy the customer needs and requirements.

Business Benefits:

- Understand the APQP requirements and process.

- Identify how the APQP process fits with an organization and its processes.

- Correlate the Plan Do Study Act (PDSA) model with the APQP cycle.

- Identify and priorities the APQP gaps within an organization.

- Provide an understanding of the type of tools needed to introduce quality products in the fastest possible time.

Who Should Attend?

- Management and employee team members from all aspects of the organization who participate in the activities associated with Advanced Product Quality Planning activities, i.e. manufacturing, engineering, sales, service, quality, etc.

- ISO/TS 16949 internal auditors or second party auditors

- Anyone involved in product quality planning activities

- Anyone involved in the implementation of ISO/TS 16949

- Anyone interested in learning more about APQP

Course Objectives:

The delegates should be able to:

- Understand the objective and phases of APQP

- Understand the interaction between the customer and supplier during APQP

- Understand the phases and timings of APQP

- Overview the types of documentation used in APQP and their purpose

- Be confident in completing a APQP exercise in a work place setting

- Be validated and certificated APQP practitioner.

Advanced Product Quality Planning Phases

- Phase 1: Plan and Define Programme - Determining customer needs, requirements and expectations using tools such as QFD. Reviewing the entire quality planning process to enable the implementation of a quality programme how to define and set the inputs and the outputs.

- Phase 2: Product Design and Development - Review the inputs and execute the outputs, which include FMEA, DFMA, design verification, design reviews, material and engineering specifications.

- Phase 3: Process Design and Development - Addressing features for developing manufacturing systems and related control plans, these tasks are dependent on the successful completion of phases 1 and 2 execute the outputs.

- Phase 4: Product and Process Validation - Validation of the selected manufacturing process and its control mechanisms through production run evaluation. Including outlining mandatory production conditions and requirements, together with identifying the required outputs.

- Phase 5: Launch, Feedback, Assessment and Corrective Action - Focuses on reduced variation and continuous improvement identifying outputs. This links to customer expectations and any future product programmes.

- Control Plan Methodology: Discusses use of control plan and relevant data required to construct and determine control plan parameters. Stressing the importance of the control plan in the continuous improvement cycle.

Course Structure:

DAY 1

1st SECTION Introduction

2nd SECTION Plan and Define Program

DAY 2

1st SECTION Product Design and Development

2nd SECTION Product and Process Validation

DAY 3

1st SECTION Launch, Feedback, Assessment and Corrective Action

2nd SECTION Control Plans and Continuous Improvement

Course dates and cost

Get in touch to arrange a free initial meeting or to find out more